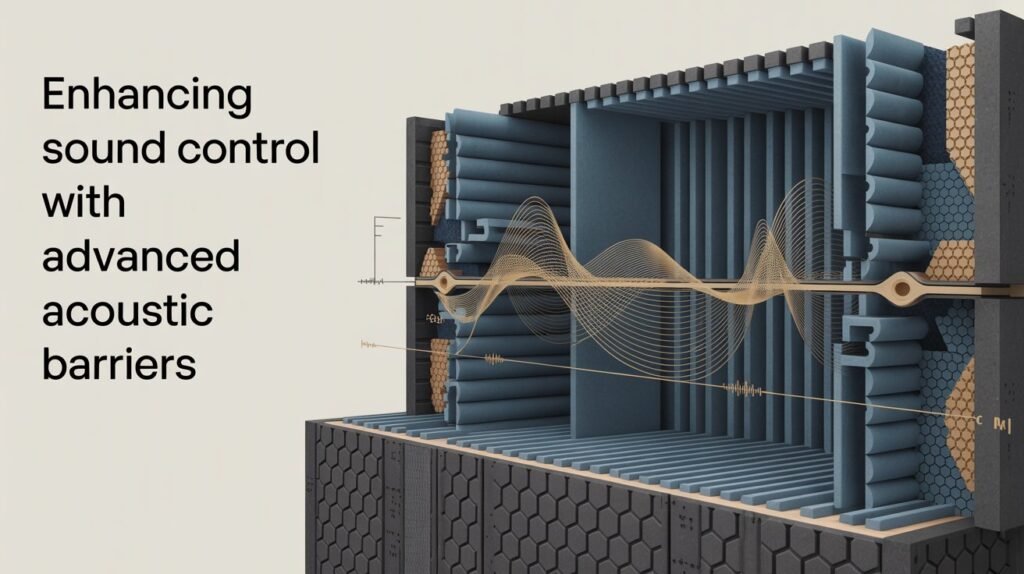

In modern industries and residential settings, controlling unwanted noise is not just a comfort issue but a necessity. Whether in vehicles, construction sites, or home environments, noise reduction is essential for safety, productivity, and overall wellbeing. This is where acoustic barriers and barrier products come into play, offering innovative solutions to manage sound effectively. Acoustic barrier products are designed to reduce airborne noise and minimize the impact of vibrations. By preventing transmission loss, these barriers help maintain quieter and more controlled environments across multiple applications.

What Are Acoustic Barrier Products?

At their core, acoustic barriers are flexible, sound-insulating materials aimed at mitigating sound and vibrations. They are particularly effective in reducing airborne noises and insulating impact sounds. Many barriers also provide an anti-vibration function, making them ideal for environments where machinery or heavy equipment is in operation. These barriers are versatile. They can be supplied in sheets, die-cut, or water jet-cut to meet precise specifications. Their flexibility allows them to conform to slightly curved or uneven surfaces, making them suitable for a wide range of applications. Moreover, acoustic barriers can be combined with acoustic foams to create bespoke laminates, providing enhanced sound absorption and transmission loss management.

Types of Acoustic Barrier Products

Polymeric Acoustic Barriers

Polymeric barriers such as C03 (1.4mm) and C09 (2.5mm) are low-density vinyl acoustic membranes. Free from lead and unrefined oils, these barriers are safe and environmentally friendly. They are designed to improve sound insulation on existing panels of metal, wood, or plastic, effectively overcoming resonance issues in lightweight composites like plywood and hollow-core panels.

Bitumen PE Foil Covered Barriers

C022 (3mm) and C023 (5mm) are diamond-embossed PE foil barriers with self-adhesive backing. These barriers prevent transmission loss and provide anti-vibration benefits. The PE foil face prevents seepage from the bitumen layer, ensuring cleanliness and facilitating bonding with other substrates to form composites.

Bitumen Aluminium Acoustic Barriers

C024 is an aluminium-faced barrier designed to withstand high-heat environments. Ideal for engine blocks, construction vehicles, agricultural machinery, and marine applications, this barrier combines bitumen, polymers, and mineral fillers for superior sound damping. Its self-adhesive backing ensures easy installation on various surfaces.

Fields of Application

Acoustic barrier products are used across multiple industries:

- Automotive: Reducing engine and road noise inside vehicles.

- Home Appliances: Enhancing performance and quiet operation of white goods.

- Lift Cabins and Metal Furniture: Minimizing structural vibrations.

- Construction and Agricultural Machinery: Mitigating sound in heavy-duty vehicles.

- Pipe Insulation: Preventing noise transmission through pipelines.

Their adaptability makes them indispensable for applications requiring both sound insulation and vibration dampening.

Foam Conversion: Complementing Acoustic Barriers

Acoustic solutions often require a combination of materials. Foam conversion plays a key role in transforming foam into technical products tailored for specific applications. Also, Foam can be cut, molded, laminated, or fabricated into custom shapes, enhancing the effectiveness of acoustic barrier products.

Foam Types

- Polyurethane Foam: Used in cushions, mattresses, and insulation.

- Polystyrene Foam: Lightweight and ideal for packaging and insulation.

- Polyethylene Foam: Durable, moisture-resistant, and used for padding or insulation.

Conversion Processes

- Cutting: Precision methods like hot wire cutting, die-cutting, or water jet cutting.

- Moulding: Shaping foam via compression or injection molding.

- Laminating: Creating multi-layered products for enhanced acoustic and thermal properties.

- Fabrication: Combining foam with other materials to produce bespoke acoustic solutions.

Applications span from packaging and seating to automotive interiors and industrial insulation, making foam conversion an essential part of the sound control ecosystem.

Class 0 Foam: Fire-Resistant Acoustic Solutions

In high-risk environments, safety and sound insulation are equally important. Class 0 foam is chemically treated to be fire-resistant while providing excellent sound absorption. Its flexibility allows it to be applied on curved or complex surfaces, making it ideal for engine rooms, generator canopies, and heavy vehicles. High-density Class 0 profiles offer exceptional acoustic performance without eroding over time. Options include foil-facing for heat resistance and combinations with polymeric barrier products to enhance overall soundproofing. Benefits include:

- Non-toxic and safe handling

- Flexibility and ease of cutting

- Self-adhesive backing for straightforward installation

- Environmentally friendly with CFC & HCFC-free materials

These qualities make Class 0 foam an indispensable solution in industrial, automotive, and marine applications.

Benefits of Acoustic Barriers

Investing in high-quality acoustic barriers and barrier products offers tangible advantages:

- Noise Reduction: Minimizes airborne noise and vibrations, creating quieter work and living spaces.

- Versatility: Can be adapted for curved, uneven, or complex surfaces.

- Enhanced Safety: Fire-resistant foam options like Class 0 ensure safe environments.

- Durability: Long-lasting performance with minimal degradation over time.

- Customization: Tailored to specific applications using foam conversion, lamination, and cutting techniques.

- Integration: Can be combined with foams or other materials for bespoke acoustic laminates.

Acoustic Barrier Installation Tips

For optimal results, consider these tips:

- Ensure intimate contact with the surface for maximum sound insulation.

- Combine with acoustic foam for improved sound absorption.

- For industrial or high-heat environments, select barriers with aluminium or foil-facing.

- Regularly inspect and maintain the barriers to prolong their lifespan.

Why Choose a Professional Supplier?

Choosing an experienced supplier like Acoustafoam ensures:

- Access to a wide range of acoustic barrier products.

- Expertise in foam conversion and bespoke acoustic solutions.

- Compliance with quality standards such as BSI ISO 9001:2015.

- Family-owned dedication, with decades of experience in delivering tailored solutions across industries.

Their technical knowledge and advanced machinery, including CNC machines and water jets, enable precise manufacturing for unique and challenging applications. From automotive to marine, their products provide reliable noise control solutions for diverse industries.

Conclusion

Effective sound control requires more than simple materials—it demands innovative acoustic barriers and expertly converted foam solutions. From industrial machinery to vehicles, and from construction sites to home appliances, these products play a crucial role in reducing noise, enhancing safety, and improving comfort. By integrating advanced acoustic barrier products, foam conversion, and fire-resistant solutions like Class 0 foam, businesses and homeowners can enjoy quieter, safer, and more efficient environments. The flexibility, durability, and customization options available today make it easier than ever to implement tailored acoustic solutions that meet specific needs. Investing in high-quality acoustic solutions is not just about reducing noise—it’s about improving quality of life, productivity, and safety in every space. Contacting professional suppliers ensures the best outcome, combining technical expertise with practical solutions that address even the most complex sound challenges.

Want more to read? Visit dDooks.